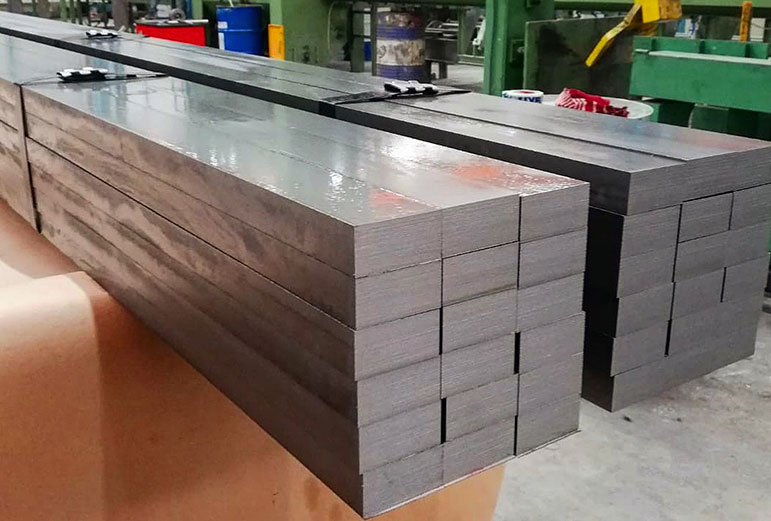

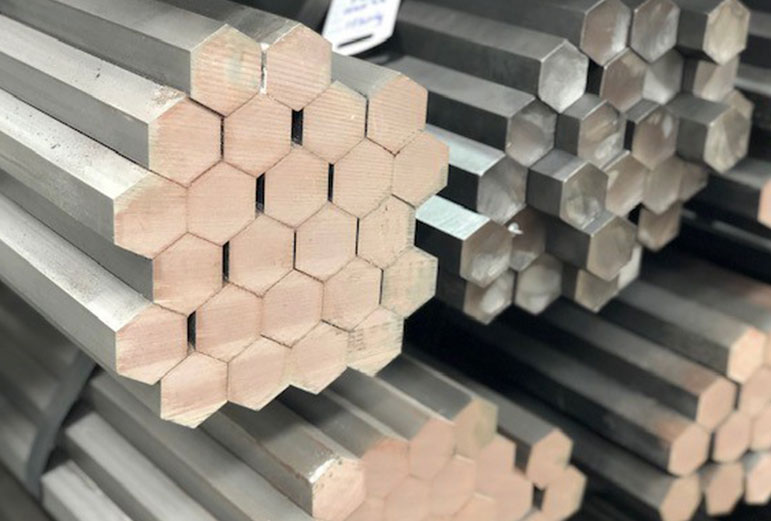

In order to supply the precise dimensional tolerances of the market, we also do bar to bar and coil to bar cold drawing. Our cold drawing plants use our hot rolling mill's bars as raw material for bar to bar cold drawing. For coil to bar cold drawing, wire rods of worldwide well known steel mills are being used as raw material.

We are capable of drawing round, flat, square and hexagonal steel bars in EN 10278 and ASTM A 108 tolerances. Other than cold drawing, we also have alternative cold finishing units such as peeling and grinding. Besides, we are capable of providing inspection certificate with crack control by using our own eddy current test devices.

DIMENSIONAL TOLERANCES FOR BRIGHT STEEL PRODUCTS ( TS EN 10278 )

| Nihai duruma göre tolerans sınıfı / Tolerance class according to final state | |||||||

| Nihai durum / Final State | h6 | h7 | h8 | h9 | h10 | h11 | h12 |

| Çekilmiş / Cold Drawn | R | R | R,S,H | R,S,H | |||

| Kabuğu Soyulmuş / Peeled | R | R | R | R | |||

| Taşlanmış / Ground | R | R | R | R | R | R | R |

| Parlatılmış / Brightened | R | R | R | R | R | R | R |

| R = Yuvarlak / Round - S = Kare / Square - H = Altıgen / Hexagon | |||||||

| Tolerans Sınıfları / Tolerance Classes | |||||||

| Anma Boyutları Nominal Dimensions (mm) |

h6 | h7 | h8 | h9 | h10 | h11 | h12 |

| > 1 - ≤ 3 | 0,006 | 0,010 | 0,014 | 0,025 | 0,040 | 0,060 | 0,100 |

| > 3 - ≤ 6 | 0,008 | 0,012 | 0,018 | 0,030 | 0,048 | 0,075 | 0,120 |

| > 6 - ≤ 10 | 0,009 | 0,015 | 0,022 | 0,036 | 0,058 | 0,090 | 0,150 |

| > 10 - ≤ 18 | 0,011 | 0,018 | 0,027 | 0,043 | 0,070 | 0,110 | 0,180 |

| > 18 - ≤ 30 | 0,013 | 0,021 | 0,033 | 0,052 | 0,084 | 0,130 | 0,210 |

| > 30 - ≤ 50 | 0,016 | 0,025 | 0,039 | 0,062 | 0,100 | 0,160 | 0,250 |

| > 50 - ≤ 80 | 0,019 | 0,030 | 0,046 | 0,074 | 0,120 | 0,190 | 0,300 |

| > 80 - ≤ 120 | 0,022 | 0,035 | 0,054 | 0,087 | 0,140 | 0,220 | 0,350 |

| > 120 - ≤ 180 | 0,025 | 0,040 | 0,063 | 0,100 | 0,160 | 0,250 | 0,400 |

| > 180 - ≤ 200 | 0,029 | 0,046 | 0,072 | 0,115 | 0,185 | 0,290 | 0,460 |

Yukarıdaki tüm toleranslar mm cinsinden eksi yönde sapma olarak alınmalıdır. All the Tolerances above must be taken as minus deviations in mm. |

|||||||

| SOĞUK ÇEKİLMİŞ LAMALAR İÇİN TOLERANSLAR TOLERANSCES FOR COLD DRAWN FLAT BARS |

|||||||

| Genişlik / Wideness | Sapma Deviation |

Sınıf CLass |

Kalınlık Thickness |

Sapma Deviation |

Sınıf CLass |

||

| mm | mm | mm | |||||

| ≤ 18 | h 11 | > 3 ≤ 6 | -0,075 | h 11 | |||

| 0 | -0,11 | ||||||

| > 18 ≤ 30 | h 11 | > 6 ≤ 10 | -0,090 | h 11 | |||

| 0 | -0,13 | ||||||

| > 30 ≤ 50 | h 11 | > 10 ≤ 18 | -0,11 | h 11 | |||

| 0 | -0,16 | ||||||

| > 50 ≤ 80 | h 11 | > 18 ≤ 30 | -0,13 | h 11 | |||

| 0 | -0,19 | ||||||

| > 80 ≤ 100 | h 11 | > 30 ≤ 50 | -0,16 | h 11 | |||

| 0 | -0,22 | ||||||

| > 100 ≤ 150 | > 50 ≤ 60 | -0,19 | h 11 | ||||

| +0,50 | -0,50 | ||||||

| > 150 ≤ 200 | > 60 ≤ 80 | -0,30 | h 12 | ||||

| +1,00 | -1,00 | ||||||

| > 200 ≤ 300 | > 80 ≤ 100 | -0,35 | h 12 | ||||

| +2,00 | -2,00 | ||||||

| > 300 ≤ 400 | |||||||

| +2,50 | -2,50 | ||||||

The tolerances shown on the table are applied only for low carbon ( C 20%) steels and low carbon free cutting steels.

For all other steel types, deviation is 50% increased.

DIMENSIONAL TOLERANCES FOR BRIGHT STEEL PRODUCTS (ASTM A 108/LEVEL ONE)

| Ölçü Size, in. (mm) |

Karbon Değeri ≤ % 0.28 Maximum of Carbon Range 0.28 % or less |

Karbon Değeri > % 0.28 - ≤ % 0.55 Maximum of Carbon Range over 0.28 % to 0.55 % incl |

Karbon Değeri ≤ % 0.55 Tavlı veya Gerilim Gidermeli Maximum of Carbon Range to 0.55 % incL, Stress Reliveved or Annealed after Cold Finishing |

Karbon Değeri > % 0.55 Maximum of Carbon Range over 0.55 % |

| Tüm toleranslar inç (mm) cinsinden ve eksi değerlerdir / All tolerances are in inches (mm) and are minus | ||||

| Yuvarlak ( 6 inç'e kadar soğuk çekilmiş veya soğuk işlenmiş) / Rounds ( Cold Drawn to 6 in. (152.40 mm) or Turned and Polished ) | ||||

| ≤ 1(25.4) Kangal Halinde / in coils | 0.002 (.051) | 0.003 (.076) | 0.004 (.102) | 0.005 (.127) |

| Çubuklar / Cut Lengths | ||||

| ≤ 1 1/2 (38.10) | 0.003 (.076) | 0.004 (.102) | 0.005 (.127) | 0.006 (.152) |

| > 1 1/2 (38.10) - ≤ 2 1/2 (63.50) | 0.004 (.102) | 0.005 (.127) | 0.006 (.152) | 0.007 (.178) |

| > 2 1/2 (63.50) - ≤ 4 (101.60) | 0.005 (.127) | 0.006 (.152) | 0.007 (.178) | 0.008 (.203) |

| > 4 (101.60) - ≤ 6 (152.40) | 0.006 (.152) | 0.007 (.178) | 0.008 (.203) | 0.009 (.229) |

| > 6 (152.40) - ≤ 8 (203.20) | 0.007 (.178) | 0.008 (.203) | 0.009 (.229) | 0.010 (.254) |

| > 8 (203.20) - ≤ 9 (228.60) | 0.008 (.203) | 0.009 (.229) | 0.010 (.254) | 0.011 (.279) |

| Altıgen / Hexagons | ||||

| ≤ 3/4 (19.05) | 0.003 (.076) | 0.004 (.102) | 0.005 (.127) | 0.007 (.178) |

| > 3/4 (19.05) - ≤ 1 1/2 (38.10) | 0.004 (.102) | 0.005 (.127) | 0.006 (.152) | 0.008 (.203) |

| > 1 1/2 (38.10) - ≤ 2 1/2 (63.50) | 0.005 (.127) | 0.006 (.152) | 0.007 (.178) | 0.009 (.229) |

| > 2 1/2 (63.50) - ≤ 3 1/8 (79.38) | 0.006 (.152) | 0.007 (.178) | 0.008 (.203) | 0.010 (.254) |

| > 3 1/8 (79.38) - ≤ 4 (101.60) | 0.006 (.152) | ... | ... | ... |

| Kare / Squares | ||||

| ≤ 3/4 (19.05) | 0.003 (.076) | 0.005 (.127) | 0.006 (.152) | 0.008 (.203) |

| > 3/4 (19.05) - ≤ 1 1/2 (38.10) | 0.004 (.102) | 0.006 (.152) | 0.007 (.178) | 0.009 (.229) |

| > 1 1/2 (38.10) - ≤ 2 1/2 (63.50) | 0.005 (.127) | 0.007 (.178) | 0.008 (.203) | 0.0010 (.254) |

| > 2 1/2 (63.50) - ≤ 4 (101.60) | 0.006 (.152) | 0.007 (.178) | 0.008 (.203) | 0.010 (.254) |

| > 4 (101.60) - ≤ 5 (127.00) | 0.011 (.279) | ... | ... | ... |

| Lama / Flats * | ||||

| ≤ 3/4 (19.05) | 0.004 (.102) | 0.005 (.127) | 0.007 (.178) | 0.009 (.229) |

| > 3/4 (19.05) - ≤ 1 1/2 (38.10) | 0.005 (.127) | 0.006 (.152) | 0.009 (.229) | 0.011 (.279) |

| > 1 1/2 (38.10) - ≤ 3 (76.2) | 0.006 (.152) | 0.007 (.178) | 0.011 (.279) | 0.013 (.330) |

| > 3 (76.2) - ≤ 4 (101.60) | 0.007 (.178) | 0.009 (.229) | 0.012 (.305) | 0.017 (.432) |

| > 4 (101.60) - ≤ 6 (152.40) | 0.009 (.229) | 0.011(.279) | 0.013 (.330) | 0.021 (.533) |

| > 6 (152.40) | 0.014 (.356) | ... | ... | ... |